Waiting Time

In this scenario, the goal is to determine the optimal waiting time between parts produced by a source station, shown in the image as S_main. This station, along with another source S_component, supplies an assembly station, displayed as Assembly, which combines components from both sources to produce the final product. Once assembled, the product moves to the Sink.

A key challenge is that components from the component source have a limited lifespan, known as the assembly condition. If too much time passes between the moment a component is prepared at the source and when the assembly process begins at the assembly, the component becomes unusable. In such cases, the assembly must discard the expired component and wait for a replacement. This not only increases costs but also disrupts the workflow, as defective components must be removed before the assembly can continue. This issue is common in processes like adhesive bonding, where adhesives can dry out if not applied within a specific timeframe.

If the waiting time between parts is too short, the source produces excess components that the assembly cannot process in time, leading to unnecessary waste. Conversely, if the waiting time is too long, the assembly is left waiting for components, delaying production. The objective is to find a balance that ensures a steady supply of components at the assembly while minimizing waste and inefficiencies.

Since the assembly is assumed to be the bottleneck in the system, the overall production rate depends on how quickly this station can receive components, assemble them, and move the assembled product to the next buffer. The optimal waiting time should match the pace at which the assembly and the source process and handle parts to maintain a continuous and efficient workflow.

What is optimized?

The processing times of the source station and the assembly station follow specific distributions. Similarly, the time required to move a component into and out of a buffer (put and get time) also follows distinct distributions. The goal is to determine the optimal waiting time at the component source, which must account for the difference between the time required by the assembly to complete processing and the time required by source to prepare its components. Essentially, the waiting time must bridge this gap to ensure a smooth workflow. By optimizing the waiting time of the component source, the earned reward (i.e. produced parts) can be maximized.

Optimization using Lineflow

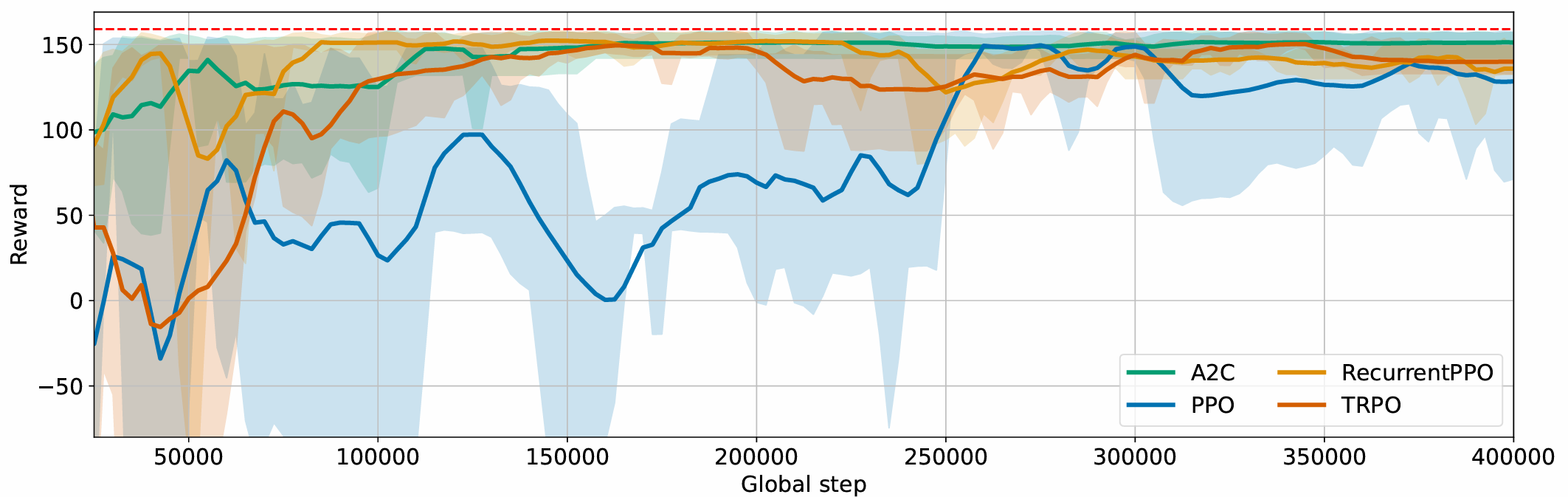

We used Lineflow to optimize the production line described above. To achieve this,

we implemented A2C, PPO, Recurrent PPO, and TRPO algorithms. The maximum reward

achieved was slightly below 160, with all algorithms successfully optimizing the waiting

time and improving the reward. An explanation for the maximum reward this line can produce

is given in the following paragraph.

Verification of the optimization

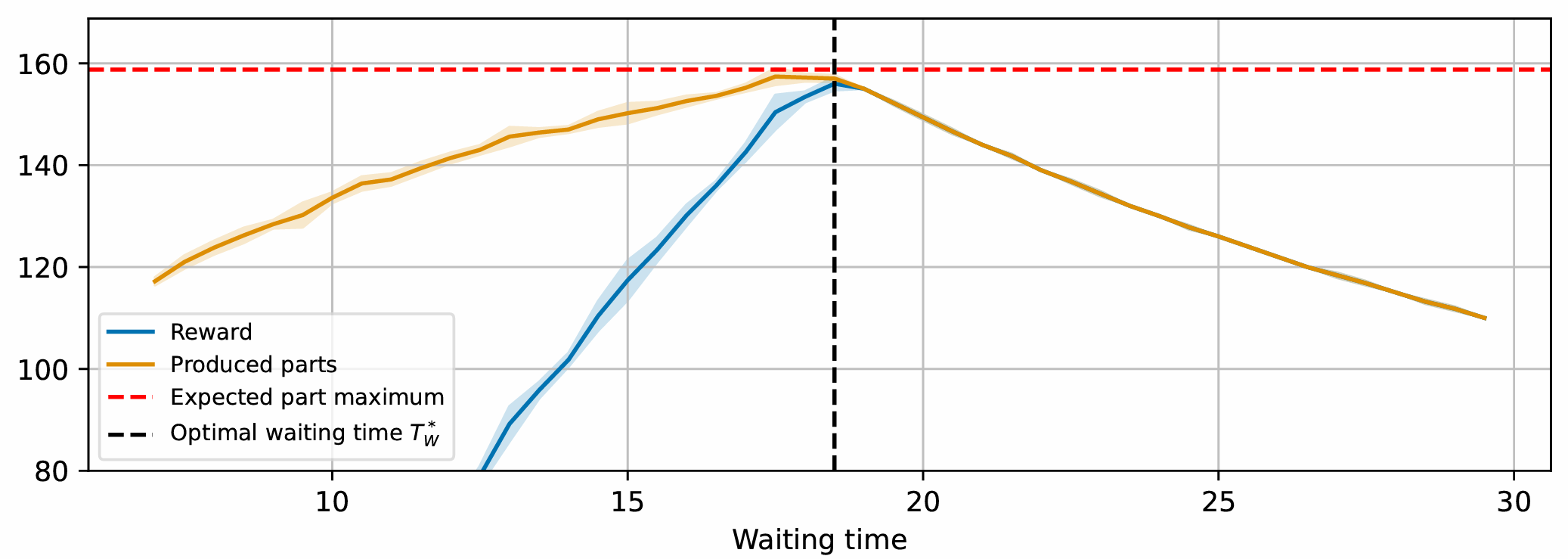

In this scenario, learning a fixed waiting time is sufficient to optimize production

efficiency. The image shown below illustrates how different waiting times at the

component source impact overall system performance, i.e. the reward.

Using the parameters mentioned above, the optimum waiting time for the line is 18.5.

If this waiting time is chosen, the line can obtain a reward averaging nearly 160.

Therefore, all algorithms used can optimize the line sufficiently.

For a detailed calculation and proof of the optimal waiting time, see (Link to Lineflow paper).

Code

import numpy as np

from lineflow.simulation import (

Source,

Sink,

Line,

Assembly,

)

def make_agent_fixed_waiting_time(line, waiting_time):

waiting_times = line['S_component'].state['waiting_time'].categories

def agent(state, env):

"""

A policy that can effectively set float waiting times by

alternating between ints

"""

index = np.argmin(np.abs(waiting_times - waiting_time))

actions = {}

actions['S_component'] = {'waiting_time': index}

return actions

return agent

def compute_optimal_waiting_time(line):

time_assembly = line['Assembly'].processing_time*1.1 + 1 + 1 + 1.1

time_source = line['S_component'].processing_time*1.1 + 1.1

return time_assembly-time_source

def make_optimal_agent(line):

waiting_times = line['S_component'].state['waiting_time'].categories

processing_time_source = line['S_component'].processing_time

def agent(state, env):

"""

A policy that can effectively set float waiting times by

alternating between ints

"""

time_assembly = state['Assembly']['processing_time'].value + 1 + 1 + 1.1

time_source = processing_time_source*1.1 + 1.1

waiting_time = time_assembly - time_source

index = np.argmin(np.abs(waiting_times - waiting_time))

actions = {}

actions['S_component'] = {'waiting_time': index}

return actions

return agent

class WTAssembly(Assembly):

def __init__(

self,

name,

R=0.75,

t_jump_max=2000,

**kwargs,

):

self.R = R

self.t_jump_max = t_jump_max

self.trigger_time = None

self.factor = None

super().__init__(name=name, **kwargs)

def init(self, random):

"""

Function that is called after line is built, so all available information is present

"""

super().init(random)

self._sample_trigger_time()

def _compute_scaling_factor(self, T_jump, E=3.1):

T = self.processing_time

S = self.processing_std

T_sim = self.t_jump_max*2

return 1/T*((T_jump*(T+S+E)) / ((self.R-1)*T_sim+T_jump) - S -E)

def _sample_trigger_time(self):

self.t_jump = np.random.uniform(

0.8*self.t_jump_max,

self.t_jump_max,

)

self.factor = self._compute_scaling_factor(self.t_jump)

self.trigger_time = self.random.uniform(0.25, 0.75)*self.t_jump_max

def _sample_exp_time(self, time=None, scale=None, rework_probability=0):

"""

Samples a time from an exponential distribution

"""

coeff = self.get_performance_coefficient()

if self.trigger_time < self.env.now < self.trigger_time + self.t_jump:

factor = self.factor

else:

factor = 1

return time*factor*coeff + self.random.exponential(scale=scale)

class WaitingTime(Line):

def __init__(

self,

processing_time_source=5,

transition_time=5,

with_jump=False,

t_jump_max=None,

assembly_condition=35,

scrap_factor=1,

R=0.75,

**kwargs,

):

self.processing_time_source = processing_time_source

self.transition_time = transition_time

self.with_jump = with_jump

self.t_jump_max = t_jump_max

self.assembly_condition = assembly_condition

self.R = R

if self.with_jump:

assert self.t_jump_max is not None

super().__init__(scrap_factor=scrap_factor, **kwargs)

def build(self):

source_main = Source(

'S_main',

position=(300, 300),

processing_time=0,

carrier_capacity=2,

actionable_waiting_time=False,

unlimited_carriers=True,

)

source_component = Source(

'S_component',

position=(500, 450),

processing_time=self.processing_time_source,

waiting_time=0,

waiting_time_step=1,

carrier_capacity=1,

carrier_specs={

'carrier': {"Part": {"Assembly": {"assembly_condition": self.assembly_condition}}}

},

unlimited_carriers=True,

actionable_waiting_time=True,

)

if self.with_jump:

assembly = WTAssembly(

'Assembly',

t_jump_max=self.t_jump_max,

position=(500, 300),

R=self.R,

processing_time=20,

NOK_part_error_time=5,

)

else:

assembly = Assembly(

'Assembly',

position=(500, 300),

processing_time=20,

NOK_part_error_time=5,

)

sink = Sink('Sink', processing_time=0, position=(700, 300))

assembly.connect_to_component_input(

station=source_component,

capacity=3,

transition_time=self.transition_time,

)

assembly.connect_to_input(source_main, capacity=2, transition_time=2)

sink.connect_to_input(assembly, capacity=2, transition_time=2)

if __name__ == '__main__':

line = WaitingTime()

agent = make_optimal_agent(line)

line.run(simulation_end=4000, agent=agent)

print(line.get_n_parts_produced())